EXPERTISE & PROJECTS

Automation and Test Systems Pty Ltd has developed a range of systems for the Pharmaceutical, Automotive and Packaging industries. Some of our projects are listed below.

AUTOMATED ALIGNMENT SYSTEM

Objective: To design a system capable of aligning and testing a critical component within a spectrometer.

Solution: Adjustment screws on the spectrometer component adjusted and calibrated the optical path. A 7 axis Motoman robot was used that allowed articulation and reach of a servo screw drive on the robot end of arm tooling. The spectrometer component was placed into a working spectrometer so that alignment data feedback could allow the robot to adjust several key adjustment screws. High-performance force sensors were used on the servo screw drive to accurately engage the adjustment fasteners on the component. The robot used a touch probe and machine vision system to accurately determine the position of the component in space. The system had 4 cells that allowed the robot to align and test 4 spectrometers and components at the same time. The system has successfully aligned many spectrometers. As a result of this system, the manufacturing of this product has stayed in Australia due to the realisation of labour cost reduction. The system has also improved yield allowing the production line to keep up with increasing spectrometer sales.

Software: The software to perform this task was written in C#. It used significant AI and advanced programming techniques, including machine vision algorithms to interpret the spectrometers visual data. The software was distributed across many apps, drivers and devices. A separate version of the spectrometer instrument program was also written to enable the alignment and testing of the instrument. Seeing this system align and test the instrument successfully was one of the most impressive achievements of our career. The complexity of the system was immense.

Expertise: Industrial Automation, Custom Automation, Process Design & Control, Manufacturing Automation, Robotic Automation, PLC programming, Industrial Robotics, Process Control, Automated Calibration & Test

INDUSTRY: Manufacturing

DENTAL CONSUMABLES ASSEMBLY MACHINE

Objective: To design and develop a control system for a customers machine that assembles dental consumables.

Solution: The control system integrated with a bowl feeder, linear vibrator, servo rotary table and 2 servo presses. The software interfaced with these devices and performed assembly sequences.

Expertise: Industrial Automation, Custom Automation, Assembly Automation, Process Design & Control, Manufacturing Automation, PLC programming, Process Control

INDUSTRY: Pharmaceutical

TRANSMISSION ASSEMBLY SYSTEM

Objective: To design and develop a system capable of assembling automotive transmission valve bodies.

Solution: The first robot cell screwed part of a valve body, the second robot cell assembled the valve body including inserting valve balls and springs, the third robot cell screwed the two halves of the valve body together.

Expertise: Industrial Automation, Custom Automation, Assembly Automation, Process Design & Control, Manufacturing Automation, Robotic Automation, PLC programming, Industrial Robotics, Robotic Assembly, Process Control

INDUSTRY: Automotive

PACKAGING LINE FOR LIQUIDS

Objective: To design a packaging line for liquids that enables filling, capping and labelling bottles for various bottle shapes and sizes.

Solution: Using 18 robots and countless auxiliary systems to enable filling, capping and labelling bottles for countless variations of bottle types “Small to large, round and square”. The systems used Kuka robots and Beckhoff control systems.

Expertise: Industrial Automation, Custom Automation, Assembly Automation, Process Design & Control, Manufacturing Automation, Robotic Automation, PLC programming, Industrial Robotics, Robotic Assembly, Process Control

INDUSTRY: Manufacturing

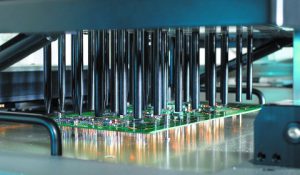

SPECTROMETER PRODUCTION LINE AUTOMATED TESTING

Objective: Design and develop automated test systems for a spectrometer production line.

Solution: Our team developed several test stations that provided automated testing of critical spectrometer components. These systems were functional test systems and In-Circuit test systems. Using test pins and O-Ring seals, mechanisms mated automatically with the spectrometer components. Standard measurement equipment was used by manufacturers such as National Instruments and Keysight Technologies for electrical interfacing and testing. Custom PCB electrical controls were also developed for functional test systems that required simulations of the spectrometers internal circuitry. Machine vision systems were also developed for accurately measuring part dimensions and quality parameters. Many C# and other software applications were developed to provide extensive testing sequences and result databases. Massive reduction in labour cost were realised with the use of these automated test systems.

Expertise: Industrial Automation, Custom Automation, Process Design & Control, Manufacturing Automation, PLC programming, In-Circuit Test Systems,

Functional Test Systems, Bed of Nails Test Fixtures, Test Fixtures

INDUSTRY: Test Engineering

PAINT CAN DEPALLETISING

Objective: To design a system that is capable of depalletizing various paint cans and placing the cans on a conveyor.

Solution: A single large robot was used to depalletize 3 pallets of paint cans at once. A slip sheet drop station handled slip sheets between pallet layers.

Expertise: Industrial Automation, Custom Automation, Assembly Automation, Process Design & Control, Manufacturing Automation, Robotic Automation, PLC programming, Industrial Robotics, Robotic Assembly, Process Control

INDUSTRY: Packaging

CAN LIDS DEPALLETIZING

Objective: To design a system that is capable of depalletizing tin can lids.

Solution: A 6 axis robot was mounted to a servo linear track that allowed the robot to depalletize 6 pallets of tin can lids at once. Once the robot had finished a pallet, the robot picked up the pallet and moved it to a pallet stack station at the end of the linear track.

Expertise: Industrial Automation, Custom Automation, Assembly Automation, Process Design & Control, Manufacturing Automation, Robotic Automation, PLC programming, Industrial Robotics, Robotic Assembly, Process Control

INDUSTRY: Packaging